|

► Regulation and Field

Green Energy !

SUMMARY

The match’s objective is to deliver ethanol barrels around the world via sea freight. In order to get barrels, teams must crop / collect and transport sugar cane up to the plant. Then teams should transport barrels to a scale via sea freight. The winner is determined by each team points achieved.

FIELD STRUCTURE

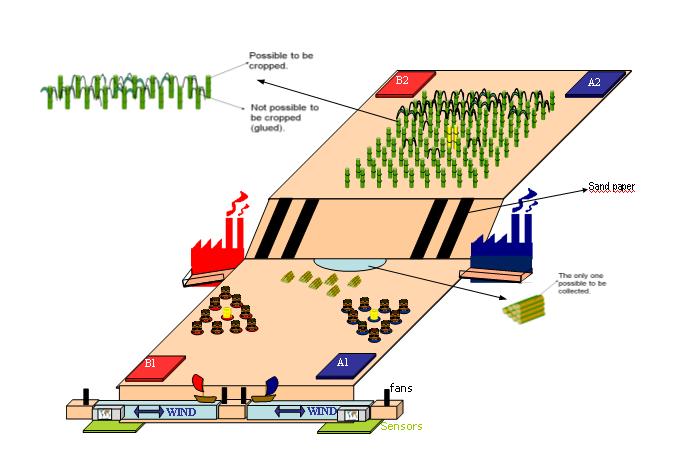

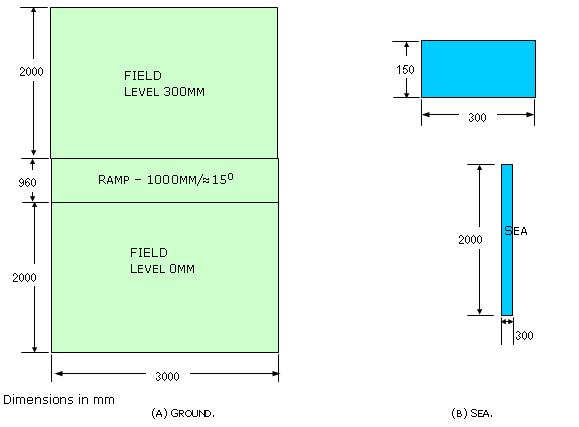

The field is illustrated in Figures 1 and 2. It is divided into:

- Level 1: 3000 x 2000 mm rectangular area (0 mm height)

- Ramp: 1000 mm length with approximately 15° of declivity

- Level 2: 3000 x 2000 mm rectangular area (300 mm height)

- Sea: two 300 x 2000 mm water fields

- One lake in the middle of the Level 1 of the field. The lake has irregular shape and it is made of propylene small balls

STARTING AREAS

Each field side has three starting areas: two field areas (400 x 400 mm) and one in the sea. Mandatory initial positions for machines and sail boat are represented in Figure 1. If any team decides to build only one ground machine, it should use the initial position 1.

MATCH

Two teams in each match and 200 seconds time limit.

SCORE

Teams will score points as sugar canes are delivered in the plant and barrels are delivered around the world, which is represented by a scale at the end of each river. The match is composed by three steps:

- Catch or crop the cane. Cane should be delivered to the processing plant*;

- Team is allowed to catch a barrel;

- Barrel should be loaded into the boat and delivered to the scale*.

*Both, sugar cane in the plant and barrels in the scale should be delivered in a stable way, which means, they should be stabilized inside the plant / scale.

Barrels are distributed in the field, as illustrated by Figure 1. As teams deliver canes to the plant, it is allowed to get ethanol barrels in the field, in the sequence defined by the numbers printed on them. A barrel should only be used by the team which released it.

Canes are represented by PVC pipes whose geometry is detailed in Table 1. Barrels are made of steel, approximately 60 mm high and radius of 30 mm. Barrels transportation can be done only with sail boats, which can be loaded only in the harbor.

There are three types of sugar-cane, and two types of barrels,

| | Task |

|---|

|

Sugar-cane to be cropped. PVC pipe with 25 mm of external diameter,

120 mm high, 20 mm underground. Each sugar cane delivered in the plant

releases one regular ethanol barrel and team scores

1 point. |

|---|

|

Sugar-cane already cropped. PVC pipe with 22 mm of external diameter,

120 mm high, 20 mm underground. Each 2

sugar canes delivered in the plant

release one regular ethanol barrel and team scores

1 point. |

|---|

|

Golden cane. PVC pipe with 25 mm of external diameter, 140 mm high,

20 mm underground. Each sugar cane delivered in the plant releases one

gold ethanol barrel and team scores 5 points.

|

|---|

|

Regular barrel. One regular barrel delivered in the scale gives

50 points for the team. |

|---|

|

Golden barrel. One regular barrel delivered in the scale gives

150 points to the team. |

|---|

SIZE AND WEIGHT MACHINES LIMITS

At the start of the competition, each robot must fit unconstrained within a 400 mm cube. Total mass of machines, including boat, should be less than 10 Kg. Sail boat fit unconstrained within a 250 mm cube, with no weight restriction; but it should not touch the bottom of the sea.

WINNER DETERMINATION

- Team with the highest score in the end of the game;

- In case of deuce, the team which delivered more barrels in the scale wins;

- When the judge recognizes the opponent side foul;

- When the judge recognizes the opponent side second penalty;

- When the opponent team does not respect 15 seconds of penalty;

- In case of none of the conditions above determine the match winner, the winner is determined by the weight of the machines: wins the team with the lighter machines set (including sail boat).

FOUL

If any foul condition below is recognized by the judge, the team will be disqualified.

- Anything but the sugar-cane is delivered in the processing plant;

- Anything but barrel is delivered in the scale;

- Anything is delivered in the opponent’s plant, sea or barrel;

- Deliver any barrier against the opponent plant, sea or barrel;

- Movement of any opponent barrel;

- Strategy that prioritizes to damage the opponent’s machines;

- Machine touches any area other than field.

PENALTY

If a team moves its barrel out from delimited area when no enough sugar canes were delivered in the plant, it will be penalized by the judge stopping immediately all of its ground machines for 15 seconds.

LIMITATION

Machines are to be manufactured only with kit that includes material and parts, except following:

- Bolts, nuts, washers and adhesives available in the workshop (it is not allowed to be used as structural elements);

- Vinyl tape used as an electric insulator;

- Grease;

- Solder for connecting wire;

- Nonfunctional decorations;

- A purchase under the expense of R$20,00 (almost US$12,00).

ENERGY SOURCES

The energy allowed in the contest is,

- Potential energy;

- Elastic energy by deformation of the springs;

- Electrical energy provided from control unit for ground machines.

- Pneumatic energy provided from control unit for the sail boats.

- Eolic energy provided by axial fans for sail boats.

The sail boats cannot use electric source.

Two fans, at the beginning and end of each river, control the direction of the wind. The following scheme of wind direction is settled,

| Time (sec) | Direction |

|---|

| 0-50 | Scale-Harbor |

| 51-90 | Harbor-Scale |

| 91-130 | Scale-Harbor |

| 131-200 | Harbor-Scale |

REMEMBER…

- Robots will be disqualified when they appear to contain a potential safety hazard;

- Contestants have 90 seconds to set up the robots and the controller unit and, after the match, team should remove the machines immediately;

- Destroying of facilities of the contest disqualifies the team;

- Strategies aimed at solely destroying or damaging the opponent robots are not in the spirit of the contest, and will not be allowed;

- Robots may not soil the playing field or an opponent machine with grease;

- Chemical processing of any component of the kit is not allowed;

- Nothing outside the contest field perimeter may be used during the contest.

Figure 1. Field of IDC 2008.

Figure 2. Detailed geometry.

MATERIAL LIST

| Item | Component | Quant. | Specifications |

|---|

| 01 | Plywood | 2 | 400 x 400 x 5 |

|---|

| 02 | Plywood | 2 | 400 x 400 x 4 |

|---|

| 03 | Compressed Paperboard | 2 | 400 x 400 x 4,5 |

|---|

| 04 | Compressed Paperbord with Holes | 2 | 400 x 400 x 3 |

|---|

| 05 | Expanded Polyestiren | 3 | 200 x 200 x 15 |

|---|

| 06 | Aluminium Sheet | 1 | 600 x 500 x 0,5 |

|---|

| 07 | Aluminium Sheet | 1 | 600 x 500 x 2 |

|---|

| 08 | Plastic Sheet | 4 | 100 x 200 x 0,5 |

|---|

| 09 | Aluminium Rod | 2 | Ф 12,7 x 200 |

|---|

| 10 | Aluminium Bar | 2 | 3,2 x 19 x 200 |

|---|

| 11 | Steel Wire | 4 m | Ф 1 |

|---|

| 12 | Rubber Sheet | 2 | 50 x 300 x 1,5 |

|---|

| 13 | Rubber Cord | 4 m | Ф 4 |

|---|

| 14 | Soldering Rod - Steel | 4 | Ф 3,2 |

|---|

| 15 | Soldering Rod - Steel | 4 | Ф 1,6 |

|---|

| 16 | Soldering Rod - Brass | 4 | Ф 3,2 |

|---|

| 17 | "Japanese" Rod | 4 | |

|---|

| 18 | Pencil | 4 | |

|---|

| 19 | Twine Wool | 1 | Ф 1 x 10000 |

|---|

| 20 | Sandpaper Sheet | 4 | tough 100 |

|---|

| 21 | Slander | 4 | |

|---|

| 22 | O Ring | 2 | Ф 85 |

|---|

| 23 | O Ring | 2 | Ф 105 |

|---|

| 24 | Aluminium Wire | 4 m | Ф 2,5 |

|---|

| 25 | Plastic Flexible Hose | 1 | Ф 4 external |

|---|

| 26 | Brass Square Rod | 1 | 4,5 x 4,5 x 500 |

|---|

| 27 | Adhesive Tape (Small) | 1 | |

|---|

| 28 | Adhesive Tape (Large) | 1 | |

|---|

| 29 | Plastic Bar (PVC) | 1 | 18 x 5,5 x 500 |

|---|

| 30 | Plastic Rod (PVC) | 1 | Ф 12 x 500 |

|---|

| 31 | Plastic Rod (PVC) | 1 | Ф 8 x 500 |

|---|

| 32 | Plastic Tube (PVC) | 1 | Ф 25 (Ext) x 500 |

|---|

| 33 | Plastic Tube (PVC) | 1 | Ф 50 (Ext) x 500 |

|---|

| 34 | Plastic Box (Rectangular) | 2 | |

|---|

| 35 | Plastic Box (Hexagonal) | 1 | |

|---|

| 36 | Corrugated Plastic Hose | 1 | Ф 31(Ext) x 2000 |

|---|

| 37 | Rubber Strip | 1 | 19 x 3 x 2000 |

|---|

| 38 | Plastic Wire | 1 | Ф 3 x 2000 |

|---|

| 39 | Aluminium Bar | 1 | 20 x 3 x 1000 |

|---|

| 40 | Aluminium Bar | 1 | 50 x 3 x 1000 |

|---|

| 41 | Aluminium "L"Profile | 1 | 19 x 2 x 1000 |

|---|

| 42 | Aluminium Tube | 1 | Ф 12,7 (Ext) x 1000 |

|---|

| 43 | Aluminium Rod | 1 | Ф 6,5 x 1000 |

|---|

| 44 | 4-pin Eletric Connector | 1 | |

|---|

| 45 | 9-pin Eletric Connector | 1 | |

|---|

| 46 | Gear Motor - Bosch | 4 | 12V |

|---|

| 47 | Motor - Sumitomo | 1 | 12V |

|---|

| 48 | Pneumatic Cylinder | 4 | |

|---|

| 49 | Black Wire | 10 m | |

|---|

| 50 | Red Wire | 10 m | |

|---|

| 51 | Micro-switch | 8 | |

|---|

| 52 | Capacitors | 8 | |

|---|

| 53 | Insulating Tape | 1 | |

|---|

| 54 | Connector to the Battery | 2 | |

|---|

| 55 | Plugs | 2 | |

|---|

| 56 | Coconut | 1 | |

|---|

| 57 | Sugar cane | 1 m | |

|---|

| 58 | Gear box | 2 | |

|---|

|

|  |